An Interview with Anthony Ableman, TIAA Certified Instructor, Director of Operations at All Tire Supply LLC, Houston, Texas (www. alltiresupply.com)

An Interview with Anthony Ableman, TIAA Certified Instructor, Director of Operations at All Tire Supply LLC, Houston, Texas (www. alltiresupply.com)

Anthony’s background and experience in the tire industry

Anthony is the second generation in the tire and wheel industry with a specific concentration in tire repair and tire and wheel service. He is a Tire Industry Association (TIA) Certified Advanced Instructor for Automotive Tire Service. He have also completed internal training programs from our suppliers on tire changing, tire repairing, wheel vibration, wheel balancing, TPMS, and vehicle lifting.

Part 2 Of 3 Part Series: How To Get Started & Do It Profitably

Give us your recommendations on how tire stores and tire repair shops can get started with TPMS as a service line, and how they can do it profitably? Or, if they are already offering it, how can they generate more revenue? n they generate more revenue?

There are a lot of solutions that are available on the market currently. Without naming particular brands of products, I would recommend manufacturers - on both the sensor and diagnostic/scan tool sides - that have a history with the vehicle OEMs. There are a lot of junk products on the market, and that will only make TPMS a headache. Some manufacturers of TPMS tools offer complete tool kits with the diagnostic tool, mechanical tools, and even marketing materials to complement it to provide information for customers in the waiting room or point of sale.

At the base line, shops will need a full-function diagnostic/programming/learn tool with OBDII functionality. Just about all Asian and European import vehicles require OBD style relearns. Domestic manufacturers are going to this style, as well which is fortunate; in the early days of TPMS the relearns were so decentralized that GM brands had over 26 different relearn procedures on their own. There is still no streamlined single process for performing a vehicle relearn, but the OBD style relearn is about as uniform as we have seen so far, and it is a really robust system in terms of making sure you really performed a good relearn as far as minimizing cross-talk and allowing the sensor IDs to be directly programmed to the ECU by the technician.

Shops will also need an array of mechanical torque tools. A lot of imports and some high-performance vehicles still use a single valve-sensor design with an anodized aluminum valve. This valve design is very corrosion prone and sensitive. Utilizing valve core torque tools and appropriate replacement components will almost eliminate the chance of galvanic corrosion that occurs between the contact of the valve and the brass of the valve core by stripping off the nickel plating of TPMS specific valve cores when technicians use non-torque valve core tools. An inch-pound torque wrench is also important to torque the nut on the sensor valve assembly. Some stem designs feature a flange that is designed to be deformed when the proper torque is reached. Also, the grommets, valves and nuts work as a system that take sensor weight, mounting, and even thickness at the valve hole into consideration when these torques are determined so it is important to maintain this regularity in fastening in the aftermarket to maintain a trouble-free system. T-10 and T-20 torque tools are also convenient. These are used on rubber snap-in valve replacement on most Ford and GM vehicles; we will also begin seeing the rubber snap-in valve style on some European imports in the North American market. The T-20 tool is used for Huf sensor systems which utilize the Alligator manufactured valve of varying lengths. These are seen on most German imports that utilize the direct system.

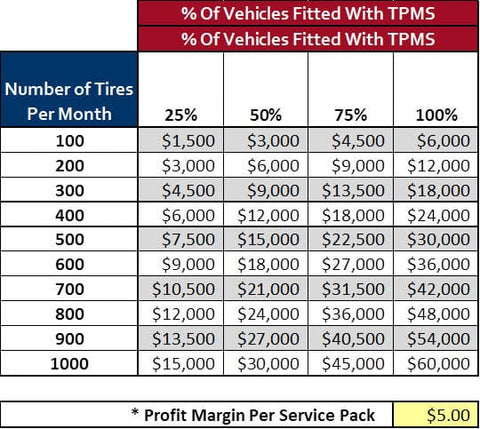

A service pack assortment is also key. Ideally, shops will have a full inventory of these items to be able to handle just about anything that comes into the shop. At a minimum I would recommend an assortment to cover the most popular vehicles. A big part of TPMS service is servicing the valve assembly by means of a service pack. This means changing the wearable components; for single piece sensor designs that means servicing the sealing valve cap, valve core (nickel plated for sensor assemblies that utilize an anodized aluminum valve), crush nut, and rubber grommet. For two-piece sensor designs that feature a rubber snap-in style valve, that means replacing the whole valve assembly (the typically come pre-assembled.

The final thing they will need will be a sensor system. Again, I would recommend going with a sensor that has OEM heritage for a couple reasons:

- Proven reliability (OEM requirements are brutal)

- Not reverse-engineered

- Utilize the same algorithms to communicate with the vehicles as the OE sensor

- Widely serviceable

I would like to speak more in-depth about the factor of widely serviceable. Some shops like to carry or sell any one of the gazillion purely aftermarket sensors available on the market. The problem with this is that the OEMs have tried to prevent this by patenting all of the best systems whereby the valve is attached to the sensor body. Since these are patented, the aftermarket sensors have to come up with some rather silly means of doing this. Now the service provider has increased his inventory costs. I already said that service pack assortments are key to starting, maintaining, and operating a well-functioning TPMS program. If you carry X-Brand of sensor replacement that only makes parts for the aftermarket, now you have to also stock service pack replacements for the line of sensors you service, as well as all of the OEM service packs to service those. Also, when your customer goes on a road trip or finds himself having a problem across town, he better hope that the shop he has to rely on to get him back on the road also carries X-Brand service packs because they are not compatible with the OEM kits he has in stock. Aftermarket products that are manufactured by OEM manufacturers utilize the same service components as they use on their OEM pieces, so after-sales service is not an issue.

How Profitable is TPMS?

Look Out for Part 3 of 3 Part Series...

Share this post

0 comment